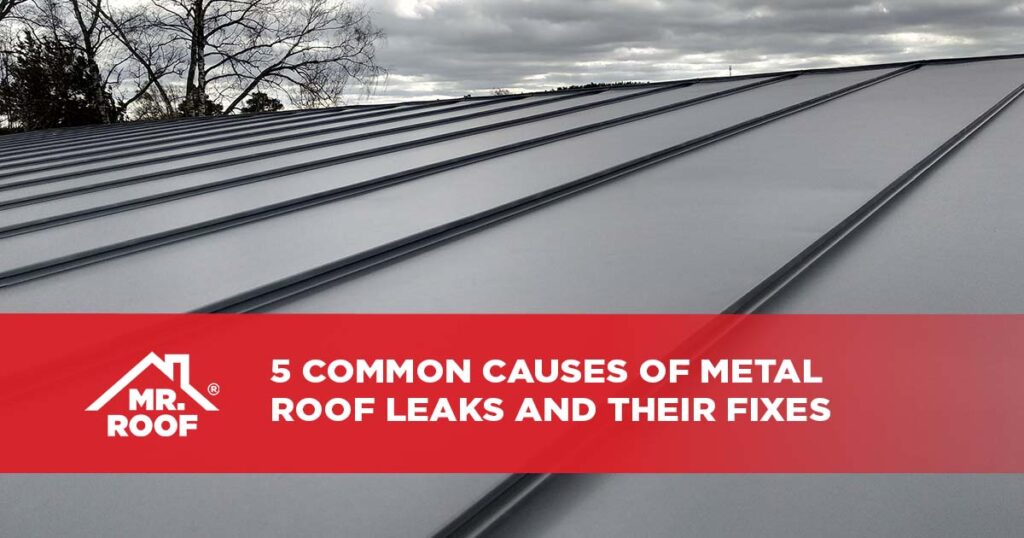

When it comes to maintaining a home in Tennessee, choosing the right Nashville roofing company is crucial, especially for metal roofing. The durability and longevity of metal roofing depend heavily on addressing common causes of leaks with expert solutions provided by a trusted Nashville roofing contractor. Understanding these causes not only helps in preventive maintenance but also ensures that your home remains well-protected against the elements, underscoring the importance of selecting a reputable roofing company in Nashville.

This article, presented by a Nashville-based roofing company, will navigate through the 5 common causes of metal roof leaks and their fixes. Staying informed can significantly extend the lifespan of your roof, highlighting the value of professional insight from a leading Nashville roofing company. Contact information for the company will be seamlessly integrated throughout the content, ensuring ease of access for those seeking high-quality roofing services in Nashville.

Metal roofing screws

Understanding the pivotal role of roofing screws in maintaining the integrity of metal roofs is essential for homeowners. Here are the key points to consider:

Installation issues

- Under-driven or over-driven screws can compromise the seal, allowing moisture to penetrate.

- Incorrect angles during installation can prevent washers from sealing properly.

- Using the wrong size, length, or type of screw can lead to leaks.

Material deterioration

- Rubber washers and seals can degrade over time due to exposure to the elements, losing their effectiveness.

- Metal screws can expand or contract with temperature changes, potentially loosening their grip.

Solutions

- Regular inspections to identify and replace faulty screws.

- Ensure proper torque and alignment during installation to maintain a weathertight seal.

Addressing these factors can significantly reduce the risk of leaks, underscoring the importance of choosing the right materials and employing experienced contractors for installation and maintenance.

Faulty flashing and sealants

Faulty flashing and sealants are pivotal concerns when addressing metal roof leaks. Common installation errors, such as over-tightening or under-tightening fasteners, placing fasteners off-center, and improper attachment or sealing of flashing, significantly contribute to the problem. These mistakes can lead to improper installation of roof-to-wall flashings, metal roof components, and fasteners, ultimately causing leaks. Additionally, the absence of sealants in crucial areas like screw holes, panel seams, and other vulnerable points can lead to moisture penetration, exacerbating the issue.

To remedy these challenges, the following steps are recommended:

- Inspect and replace flashing and sealants: Regularly check for and promptly address any signs of wear or damage to flashing and sealants.

- Proper installation practices: Ensure that all fasteners are correctly tightened and placed, and that flashing is properly attached and sealed. This prevents moisture from entering through gaps.

- Use high-quality materials: Opt for superior sealants like super silicon or extreme silicon, known for their strong adhesion to cement and UV protection. These materials provide a durable barrier against water intrusion.

Engaging a professional Nashville roofing contractor for the repair of metal roof leaks, especially when it involves fixing damaged flashing, is crucial. Regular inspections and maintenance play a significant role in preventing metal roof problems, including leaks, ensuring the longevity and performance of your roofing system.

Rust and corrosion

Rust and corrosion are formidable adversaries to metal roofing, but with vigilant care and the right preventative measures, their impact can be significantly mitigated. Regular inspections are crucial; they enable homeowners to catch early signs of rust, allowing for timely intervention. When rust is spotted, removing it with a wire brush, soapy water, and then applying a protective coating can prevent further damage. For added protection, options include:

Protective coatings

Utilize elastomeric, silicone, or acrylic coatings to shield your metal roof from the elements.

Galvanized metal roofing

This method involves treating the metal with liquified zinc, adding an extra layer of defense against corrosion.

Maintenance tips

- Clean the roof thoroughly before applying any paint or primer to ensure maximum adhesion and effectiveness.

- Regularly clear away debris and trim tree branches to prevent moisture buildup, which can accelerate rust formation.

By adhering to these guidelines and choosing high-quality materials, homeowners can extend the lifespan of their metal roofs and maintain their property’s integrity against the harsh elements.

Improper installation and structural issues

Improper installation and structural issues can severely compromise the integrity of metal roofs, leading to leaks and a reduction in the roof’s lifespan. Here are critical points to consider:

Installation errors and their impact

- DIY risks: Undertaking metal roof installation without professional expertise can lead to injuries, resulting from falls or improper handling of materials and tools.

- Aesthetic concerns: Incorrectly installed metal roofs can appear crooked or mismatched, detracting from a property’s overall appearance.

- Structural damage: Inadequate installation can cause structural issues, such as overlapping seams that allow water to pool and stray screws that create unexpected holes.

The value of professional installation

- Access to quality materials: Professional Nashville roofing contractors have access to high-quality, durable materials that outperform cheaper alternatives.

- Cost-effectiveness: Roofing contractors possess the necessary tools and equipment, often receiving materials at discounted rates, making the professional installation more cost-effective than DIY efforts.

- Warranty and quick completion: A reputable Nashville roofing company ensures the job is done correctly, within a short timeframe, and provides a warranty for their work, offering peace of mind to homeowners.

Preventive measures and regular maintenance

- Inspection and maintenance: Regular cleaning and inspection can identify potential issues such as open laps and missing parts before they escalate into leaks.

- Professional assessment: Engaging a Nashville roofing contractor for regular inspections can help extend the life and functionality of a metal roof, ensuring any installation errors are promptly addressed.

Choosing a Nashville roofing company with a proven track record, extensive knowledge, and the right qualifications is crucial for avoiding improper installation and ensuring the longevity of your metal roofing system.

Conclusion

Throughout this exploration of metal roofing’s common pitfalls and their remedies, the importance of recognizing the contributing factors to leaks – from compromised roofing screws and faulty flashing to rust, corrosion, and installation errors – becomes undeniably clear. Acknowledging these issues not only aids in prevention but also ensures the robustness and longevity of metal roofing systems. The insights provided remind property owners of the pivotal role regular maintenance and professional expertise play in safeguarding one of their most significant investments.

To mitigate these challenges effectively, engaging with a trusted and experienced Nashville roofing company like Mr. Roof becomes essential. Our expertise in addressing these common causes with precision and care underscores the value of professional intervention. For those looking to protect and maintain their metal roofing with confidence, contact Mr. Roof for a free roofing estimate. Embracing such preventative and corrective measures will not only enhance the durability of your roof but also bolster its ability to withstand the elements, ensuring the safety and security of your home for years to come.